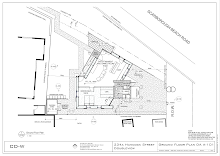

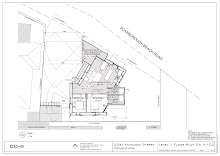

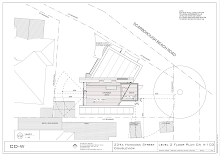

Since we are building straw bale infill walls in a timber framed construction, we needed to create a raised upstand on the perimetre for the bales to site on. Not only would this keep the bales dry and off the ground, it would also give us a exposed concrete footing (sans joints) to track and keep a check on any termites.

We already have quite a height restriction on the site, so the only way we could achieve the 2 and half floors we wanted at a 9m finished roof height was to make sure the interior finished floor level was at the same as the external finished level. The raised upstand was really the only option.

When we did a presentation of the project for our colleagues at work (who also all coincidentally happen to be architects), one of the things that was raised was our upstand detail. Everyone agreed it was expensive, excessive, and no builder would attempt it without dumping a "risk or contingency" chunk over the cost.

We have a C channel running along the inner edge of the upstand which we hoped would double up as formwork and later on as a continuous ducting recess behind a skirting board. The problem was -how do we suspend this channel in mid air while concrete is poured under it.

We finally worked out a system where we screwed equal lengths of 100mm widths of the standard plywood at intervals on the C channel. These were then screwed back onto the main external formwork at intervals - the external plywood was held in place by bamboo stakes driven into the ground.

The C channels were then supported on double stacks of standard plastic concrete chairs which were rested on the reinforcement bars cantilevering into the footing.

Now this held the C channels in place in principle, however, the weight of the concrete against the plywood would surely bend the entire thing out of shape!

The concreter we hired for Wednesday morning (morning of the pour) came around to have a quick check - i think he didnt trust 3 architects trying to do his job ;-) - quite rightly....!

The plywood was far too unstable to hold in the concrete. So his suggestion was simple and effective - drive in metal stakes at intervals into the ground surrounding the external formwork and wedge in more ply panels using the metal stakes as a sturdy support.

Once that was done, the formwork wouldnt even yield an inch!

Christian and Gian heaved a sigh of relief!

And we didnt bother to calcuate how much money we saved by doing it ourselves.... :-)

No comments:

Post a Comment