The two weeks leading up to today was one of great tensions, exhilaration, physical prowess and emotional breakdowns.

Well ok I am exaggerating on the emotional breakdown part of it. We were pretty flat out, and there was no time for any breakdowns.

Before I digress and start the chatter, I need to say a MASSIVE THANKS to Gian, without whom our crazy deadline would have gotten the better of us. Thanks to his common sense, great practical ideas, and most important his availability, we were able to complete the formwork in time for the pour, and in perfect timing - 12 hours before the start of the most rainy week Perth has had this year… A day late, and we would have had to postpone the pour, and the rain would have ruined our prepared trenches. So the timing was fantastic.

When Christian suggested we build the plywood formwork ourselves, I was quite confident that we would be able to manage it. We had a fantastic set of tools, which we were both starting to get better and better at using. We planned to do the entire formwork out of 16mm plywood and spent a lot of time working out the complicated edge upstand detail. We spent the weekend of the 4th and 5th digging more trenches and testing the edge detail on site – and we thought we might just be able to pull it off…..

Gian spent most of the 2 weeks leading up to this day finishing the trenches, cutting the reinforcement to size and prefabricating the upstand formwork so we could attach it on. On the weekend, we managed to start setting up the formwork, and the Sunday, Monday and Tuesday were absolute crazy with Gian working all day on site, Christian joining him by afternoon, me in the evening, and us trying to work till 11 or 12 at night on site making as little noise as possible!!

Here are some photos of the formwork before the concrete was poured. I will try to explain as best as I can for those non-architects out there who are interested.

Our slab is a 100mm thick concrete slab, with a 30mm thick foam insulation under it (the blue stuff). Under the foam insulation, we have a waterproofing layer – which is the thick black plastic stuff. The waterproofing layer needs to be sealed, so where it overlapped, or where it had a hole for pipes or penetrations to go through, we sealed it up with heavy duty tape.

We needed a lot of tape.

And when I was sent to Bunnings to buy more tape, I came back with 5 different colours, much to Chritians amusement – but they were all so cool! Anyway, if anyone digs up our slab in the future they will find patches of bright red, lemon yellow, cobalt blue, sour green colours of haphazard taping all over.

Wonderful!

Anyway, the slab sits on a footing of approximately 600 to 700mm wide x 300mm deep that runs the full perimeter of the slab. Now if we had stopped there, the formwork would have been easy.

But we didn’t.

Since we are building straw bale walls, we wanted to create a raised upstand on the perimetre for the bales to site on.

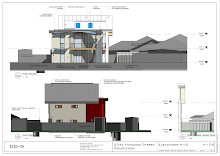

(to be continued................................) First Level of the toilet block goes up - Bricks shown here are 200x200x600 eco bricks. They are aerated concrete. On the interior, we will have drywall or render; and on the exterior, our famous red metal! Jerry, a mate of a mate, happens to be a brickie and knocked this up on a weekend.....

First Level of the toilet block goes up - Bricks shown here are 200x200x600 eco bricks. They are aerated concrete. On the interior, we will have drywall or render; and on the exterior, our famous red metal! Jerry, a mate of a mate, happens to be a brickie and knocked this up on a weekend.....